High Precision Machining Secrets Revealed: What Aerospace Experts Don't Want You to Know

- helvinbacareza

- Dec 27, 2025

- 4 min read

Updated: Dec 29, 2025

The aerospace manufacturing process demands tolerances measured in thousandths of inches. Yet many manufacturers continue making fundamental shop-floor errors that compromise precision aerospace components. These technical oversights cost millions in rejected parts and delayed deliveries.

Tool Deflection: The Silent Precision Killer

Tool deflection represents the most overlooked factor in aerospace machining operations. Standard tooling configurations flex under cutting forces, creating dimensional variations that exceed aerospace tolerances.

Long, slender endmills deflect measurably during deep pocket machining. This deflection increases proportionally with cutting depth and material removal rates. The resulting parts exhibit tapered walls and dimensional inconsistencies that require costly rework.

Precision aerospace components require specialized tooling strategies. Carbide tools with optimized length-to-diameter ratios minimize deflection. Workholding systems must provide maximum rigidity while maintaining access for complex geometries.

Tool deflection calculations involve Young's modulus, moment of inertia, and applied forces. Most shops rely on experience rather than engineering analysis. This approach fails consistently when machining critical aerospace parts.

Advanced manufacturers utilize finite element analysis to predict tool deflection before cutting begins. These calculations guide tool selection, cutting parameters, and workholding design for each specific component geometry.

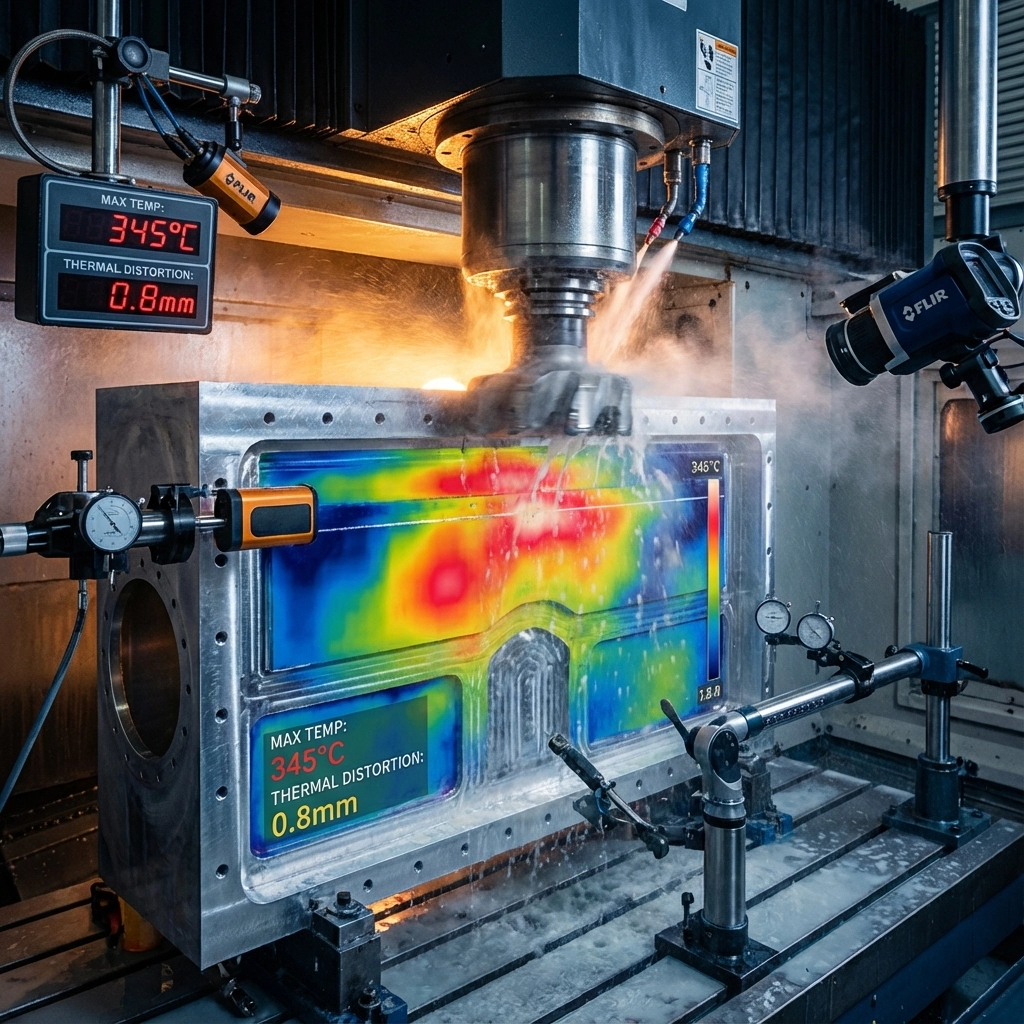

Thermal Expansion: Temperature Control Failures

Temperature variations cause dimensional changes that destroy precision in aerospace machining operations. Material expansion coefficients create predictable dimensional shifts as temperatures fluctuate during production cycles.

Aluminum alloys expand approximately 0.000013 inches per inch per degree Fahrenheit. Titanium alloys exhibit different expansion rates. These differences compound across large aerospace components, creating significant dimensional variations.

Most shops monitor ambient temperature but ignore workpiece temperature during machining. Cutting generates substantial heat that raises part temperatures well above ambient levels. This thermal growth affects measurements and final dimensions.

Temperature-controlled environments maintain consistent conditions throughout the aerospace manufacturing process. Coolant systems regulate workpiece temperatures during cutting operations. Measurement protocols account for thermal effects on both parts and inspection equipment.

Thermal expansion compensation requires real-time temperature monitoring and dimensional adjustments. Coordinate measuring machines operate in temperature-controlled rooms for accurate measurement of precision aerospace components.

Chip Management: Overlooked Quality Factor

Improper chip management creates surface finish defects and dimensional inconsistencies in aerospace machining. Chips that remain in cutting zones cause tool wear, surface scratches, and measurement errors.

Aluminum chips weld to cutting tools under high temperatures. These built-up edges alter effective tool geometry and create poor surface finishes. Titanium chips generate extreme heat and can ignite under certain conditions.

Conventional chip removal relies on flood coolant and compressed air. These methods fail to clear chips from deep pockets and complex geometries common in aerospace components. Residual chips contaminate subsequent operations.

High-pressure coolant systems provide directed chip evacuation. Through-spindle coolant delivery reaches confined cutting zones. Programmable coolant timing coordinates with tool paths for optimal chip management.

Chip breaking geometries on cutting tools control chip formation and evacuation. Proper chip breaking prevents long, stringy chips that tangle in workholding fixtures and damage part surfaces.

Setup Rigidity: Foundation of Precision

Machine setup rigidity directly impacts achievable tolerances in aerospace manufacturing. Insufficient rigidity allows cutting forces to deflect the entire workholding system, creating dimensional errors throughout the machining cycle.

Standard vises and fixtures provide inadequate support for aerospace machining forces. Workpiece deflection under cutting loads creates non-uniform material removal and surface finish variations.

Fixture design must consider all cutting force directions and magnitudes. Support points require strategic placement to minimize workpiece deflection while maintaining tool access. Clamping forces must distribute evenly without distorting thin-wall aerospace components.

Custom workholding fixtures designed specifically for aerospace parts provide maximum rigidity. Modular fixturing systems allow reconfiguration for various component geometries while maintaining setup integrity.

Finite element analysis validates fixture designs before manufacturing. These simulations predict deflection patterns and identify areas requiring additional support. Proper fixture design eliminates setup-related quality issues.

Measurement System Inadequacy

Standard measurement equipment lacks accuracy for precision aerospace components. Micrometers and calipers provide insufficient resolution for aerospace tolerances. Environmental factors affect measurement reliability.

Temperature variations cause dimensional changes in both parts and measuring instruments. Calibration intervals must account for environmental conditions and usage patterns. Measurement uncertainty calculations determine actual achievable tolerances.

Coordinate measuring machines provide three-dimensional measurement capability essential for complex aerospace geometries. Proper CMM programming accounts for measurement strategy, probe configuration, and environmental compensation.

Statistical process control monitors dimensional trends throughout production runs. Control charts identify process variations before parts exceed tolerance limits. Real-time feedback enables immediate corrective actions.

Process Documentation and Control

Many shops lack comprehensive process documentation for aerospace machining operations. Undocumented processes create inconsistency between operators and shifts. Critical parameters remain undefined and uncontrolled.

Aerospace manufacturing process requirements mandate documented procedures for every operation. Tool selection, cutting parameters, measurement protocols, and quality checks require formal specification and control.

Work instructions must specify exact tooling, workholding, and measurement requirements. Operator training programs ensure consistent execution of documented procedures. Process changes require formal approval and documentation updates.

Advanced Monitoring Technologies

Real-time process monitoring detects variations during machining operations. Spindle load monitoring identifies tool wear and cutting condition changes. Vibration analysis reveals developing problems before quality issues occur.

Adaptive control systems automatically adjust cutting parameters based on real-time feedback. These systems maintain consistent cutting conditions despite material variations and tool wear progression.

Machine learning algorithms analyze historical production data to optimize cutting parameters. Predictive maintenance schedules prevent machine failures that compromise part quality and delivery schedules.

Vanguard Tech Technical Expertise

These technical challenges require comprehensive understanding of aerospace manufacturing principles. Vanguard Tech addresses each critical factor through systematic engineering analysis and process optimization.

Our technical approach combines advanced tooling strategies, thermal management systems, and precision workholding solutions. Each aerospace project receives customized process development based on specific part requirements and material characteristics.

Quality systems integrate real-time monitoring with statistical process control for continuous improvement. Our facility maintains environmental controls essential for precision aerospace components manufacturing.

Contact Vanguard Tech to discuss your precision aerospace component requirements. Our technical team provides comprehensive solutions that address fundamental machining challenges through proven engineering principles.

Comments