The Ultimate Guide to AS9100 Machining: Everything Defense Contractors Need to Succeed in 2026

- helvinbacareza

- Jan 2

- 4 min read

AS9100 machining represents the aerospace industry's most stringent quality management standard for defense manufacturing solutions. This certification framework combines all ISO 9001 requirements with approximately 100 additional aerospace-specific criteria, establishing mandatory protocols for suppliers producing flight-critical and mission-critical components.

AS9100 Certification Requirements for Defense Manufacturing

AS9100 certification mandates comprehensive quality management systems specifically designed for aerospace and defense applications. The standard requires organizations to implement risk mitigation protocols, continuous improvement processes, and strict documentation procedures across all manufacturing operations.

Core certification requirements include configuration management systems that address product performance throughout complete operational lifecycles. Risk identification and management protocols ensure quality and safety compliance for all manufacturing processes. Aerospace supplier management systems prevent counterfeit parts infiltration while maintaining supply chain integrity.

Product safety functions as a non-negotiable, mandatory requirement under AS9100 standards. Material traceability and batch control systems require supplier-provided certification validation for all components and raw materials entering production processes.

2026 Compliance Landscape for Defense Contractors

Defense contractors face intensifying regulatory demands in 2026. Primary operational shifts focus on rapid capability deployment and high production rates, requiring suppliers to deliver complex assemblies with reduced lead times and minimal manufacturing delays.

Compliance requirements continue evolving as tolerance specifications tighten and defense systems advance in complexity. Defense manufacturing solutions must accommodate these changing specifications while maintaining AS9100 certification standards.

Essential 2026 investments for defense contractors include advanced machining capabilities, particularly 5-axis CNC machining systems for lightweight materials and complex geometries. Lean manufacturing implementation and program management tools enable efficient production workflows. Real-time process monitoring and data analytics systems provide immediate feedback for quality control operations.

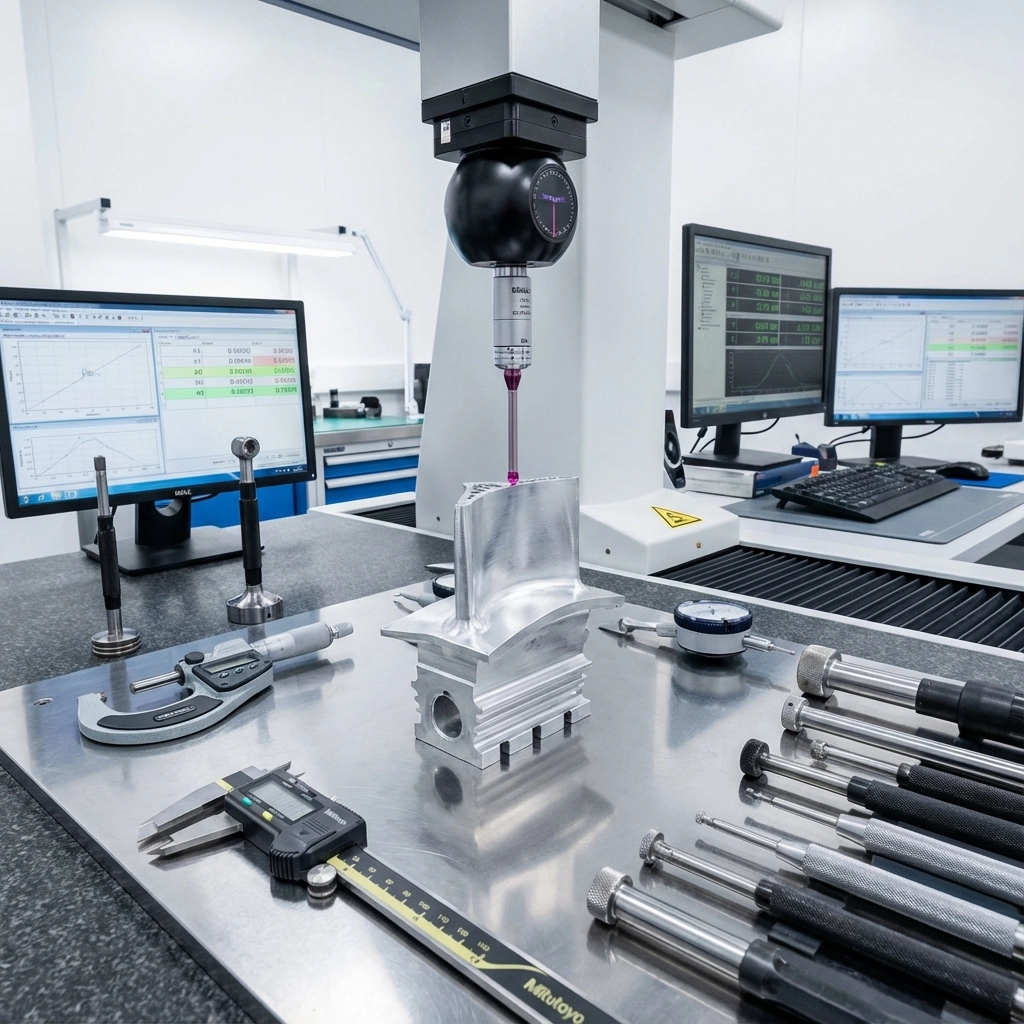

Enhanced inspection, metrology, and verification infrastructure supports comprehensive quality assurance protocols required under AS9100 standards.

IA9100 Standard Updates and Implementation Requirements

The International Aerospace Quality Group releases new IA9100 series standards in 2026, establishing updated protocols for aerospace quality management. The transition period extends until 2029, providing organizations time for systematic implementation of new requirements.

IA9100 introduces proactive process control requirements that mandate active outcome prediction and control rather than reactive validation procedures. Organizations must implement real-time Statistical Process Control (SPC), Measurement System Analysis (MSA), and Design of Experiments (DOE) protocols.

Live ERP-integrated control plans replace traditional end-of-run inspection procedures with systems that actively monitor and prevent quality issues before occurrence. Product safety requirements transition from recommended practices to mandatory organizational processes embedded throughout quality management systems.

High Precision Machining for AS9100 Compliance

High precision machining capabilities form the foundation of AS9100-compliant manufacturing operations. Defense contractors require exceptional consistency and repeatability across all machining processes to meet aerospace quality standards.

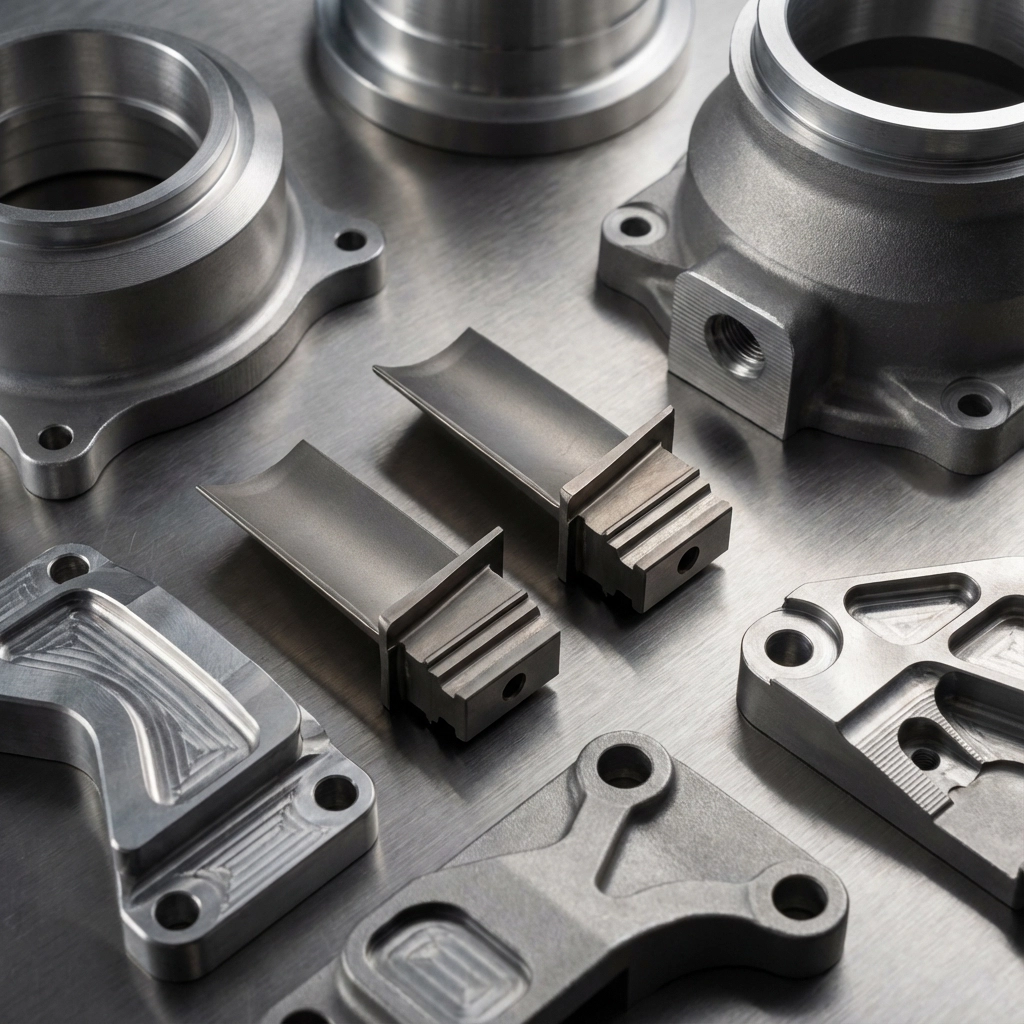

Five-axis CNC machining provides critical capabilities for defense platforms incorporating lightweight materials and multi-function designs. This technology enables component machining from multiple angles in single setups, improving uniformity and reducing variance between machining stages.

Advanced first-article inspection processes validate initial production runs against engineering specifications. Enhanced in-process verification routines monitor manufacturing parameters throughout production cycles. Rigorous calibration cycles maintain measurement system accuracy for quality control operations.

Integrated digital traceability systems track component history from raw material receipt through final assembly delivery. These systems provide complete documentation for regulatory compliance and customer requirements.

Turnkey Manufacturing Solutions for Defense Applications

Turnkey manufacturing provides comprehensive production solutions that encompass design support, material procurement, machining operations, assembly processes, and quality assurance protocols. These integrated services enable defense contractors to streamline supply chain management while maintaining AS9100 compliance.

Turnkey manufacturing solutions include complete project management from initial design review through final delivery. Material sourcing and procurement services ensure AS9100-certified suppliers throughout the supply chain. Integrated quality management systems provide comprehensive documentation and traceability for all manufacturing operations.

Assembly and sub-assembly services accommodate complex defense system requirements while maintaining strict quality control protocols. Final inspection and testing procedures validate product performance against customer specifications before delivery.

Manufacturing Process Control and Documentation

AS9100 framework requires meticulous process documentation, disciplined execution of established procedures, and consistent adherence to internal standards. Documentation systems must capture all manufacturing operations, quality control procedures, and material handling processes.

Process control procedures include statistical monitoring of critical manufacturing parameters, real-time feedback systems for production adjustments, and comprehensive corrective action protocols for non-conforming products.

Supplier qualification programs ensure all vendors maintain AS9100 certification and demonstrate consistent quality performance. Regular audits and performance reviews validate ongoing compliance with aerospace quality standards.

Technology Integration for 2026 Compliance

Advanced manufacturing technologies enable defense contractors to meet evolving AS9100 requirements while improving operational efficiency. Computer-aided manufacturing systems integrate design data with production equipment for consistent part quality.

Automated inspection systems provide real-time feedback on dimensional accuracy and surface finish parameters. Digital twin technology enables virtual validation of manufacturing processes before physical production begins.

Machine learning algorithms analyze production data to predict quality issues and optimize manufacturing parameters. Integrated enterprise resource planning systems coordinate material flow, production scheduling, and quality management activities.

Implementation Roadmap for Defense Contractors

Successful AS9100 implementation requires systematic planning and resource allocation across multiple organizational functions. Initial assessment activities evaluate current quality management systems against AS9100 requirements to identify improvement areas.

Documentation development includes creation of quality manuals, work instructions, and process control procedures that meet AS9100 standards. Employee training programs ensure personnel understand new procedures and quality requirements.

System integration activities coordinate quality management software with existing manufacturing and business systems. Pilot production runs validate new procedures before full-scale implementation across all manufacturing operations.

Certification preparation includes internal audits, corrective action implementation, and third-party assessment coordination. Ongoing maintenance activities ensure continued compliance with AS9100 requirements and preparation for IA9100 transition.

Strategic Advantages of AS9100 Certification

AS9100 certification provides access to defense and aerospace contracts requiring certified suppliers. Enhanced quality management systems reduce manufacturing defects and customer complaints while improving operational efficiency.

Improved supplier relationships result from demonstrated quality capabilities and regulatory compliance. Competitive advantages include preferential supplier status with major defense contractors and access to complex, high-value manufacturing projects.

Risk mitigation benefits include reduced liability exposure and improved customer confidence in manufacturing capabilities. Long-term business growth opportunities expand through qualification for larger defense programs and international aerospace markets.

Defense contractors must begin preparation for IA9100 transition requirements to maintain competitive positioning and regulatory compliance. Organizations implementing comprehensive AS9100 systems position themselves for continued success in the evolving defense manufacturing landscape.

Comments